MedEco XGB

The bioplastic for rigid extrusion components with a particularly non-slip surface.

Process characteristics

- Very good workability

- Low temperatures - high energy savings

- Processing instructions

Sustainability aspects

- 99% bio-based

- Very low footprint

- Biodegradable according to EN 13432

- Recycling options

- Sustainability factsheet

Applications

Our MedEco XGB is ideal for applications that require a rigid, non-slip material with high surface hardness.

- Bottles and cans

- Blister packaging

- Pipes and profiles

CO2e reduction compared to

PET

PP

HDPE

ABS

Scope: CO2 savings potential for the compound in cradle-to-gate.

Concrete results depend on other factors such as product geometry and processing technology.

We are happy to calculate the potential for your application.

Products & Processes

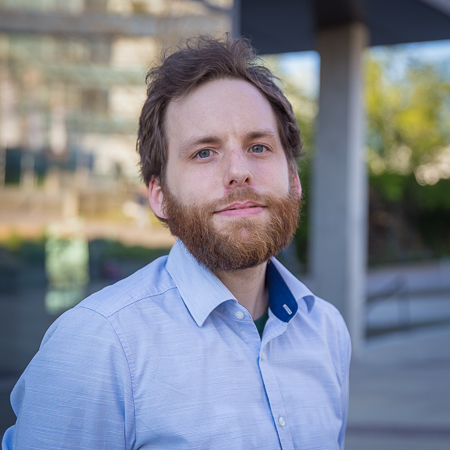

“High productivity, dimensional stability and a wonderfully comfortable surface. Your new sustainable material for opaque blisters and profiles.”

Book a consultation!

Together, we explore how to future-proof your application in a pragmatic and straightforward way. Let's uncover the sustainability potential you can leverage with us.

Book an appointment directly to our calendar.

We will discuss your case and answer any questions you may have.

Alternatively send us an email or call us: